Introduction to TMT Global Technology Ltd

TMT Global Technology Ltd is a distinguished entity in the manufacturing landscape, recognized for its commitment to excellence since its inception. Founded with a vision to innovate and elevate manufacturing standards, TMT has carved a niche in the production of high-quality control cables and related products. The company holds a steadfast mission to deliver unparalleled safety and performance solutions to industries worldwide, reinforcing its reputation as a trusted name in the market.

At the heart of TMT is a robust set of core values that guide its business operations and interactions. Integrity, quality, and customer satisfaction are paramount, ensuring that every product meets rigorous industry standards. By fostering a culture of continuous improvement and embracing cutting-edge technology, the organization remains at the forefront of manufacturing practices. TMT’s adeptness in the design and production of control cables positions it as a key player in sectors that demand dependability and precision.

The global market recognizes TMT Global Technology Ltd not only for its exemplary products but also for its strategic vision. As industries increasingly rely on sophisticated technology, TMT’s expertise in manufacturing control cables plays a crucial role in meeting these evolving demands. The company’s products are essential for various applications, ranging from automotive to telecommunications, making them integral to the functionality of countless systems worldwide. With a focus on sustainable manufacturing processes, TMT is committed to minimizing environmental impact while delivering products that adhere to the highest standards of quality and safety.

Overall, TMT Global Technology Ltd’s unwavering dedication to excellence and innovation positions it as a pivotal player in the manufacturing sector, particularly in the control cables market. This foundational commitment highlights the company’s significant influence in the global arena and underscores its role in driving technological advancements across various industries.

Understanding Control Cables

Control cables play a crucial role in the functioning of various electronic and mechanical systems across multiple industries. These cables are designed to transmit signals or power between devices, ensuring that operations are carried out efficiently and reliably. Typically composed of multiple conductors, control cables are often sheathed in protective materials to guard against environmental factors, ensuring longevity and performance.

There are various types of control cables, each tailored to specific applications. For instance, unshielded twisted pair cables are commonly used in telecommunications, where they facilitate data transmission by reducing electromagnetic interference. Shielded cables, on the other hand, are favored in industrial settings due to their enhanced protection against external noise, making them suitable for environments with heavy machinery. Moreover, multi-core cables are frequently employed in automotive applications, where their compact design and versatility enable complex wiring configurations.

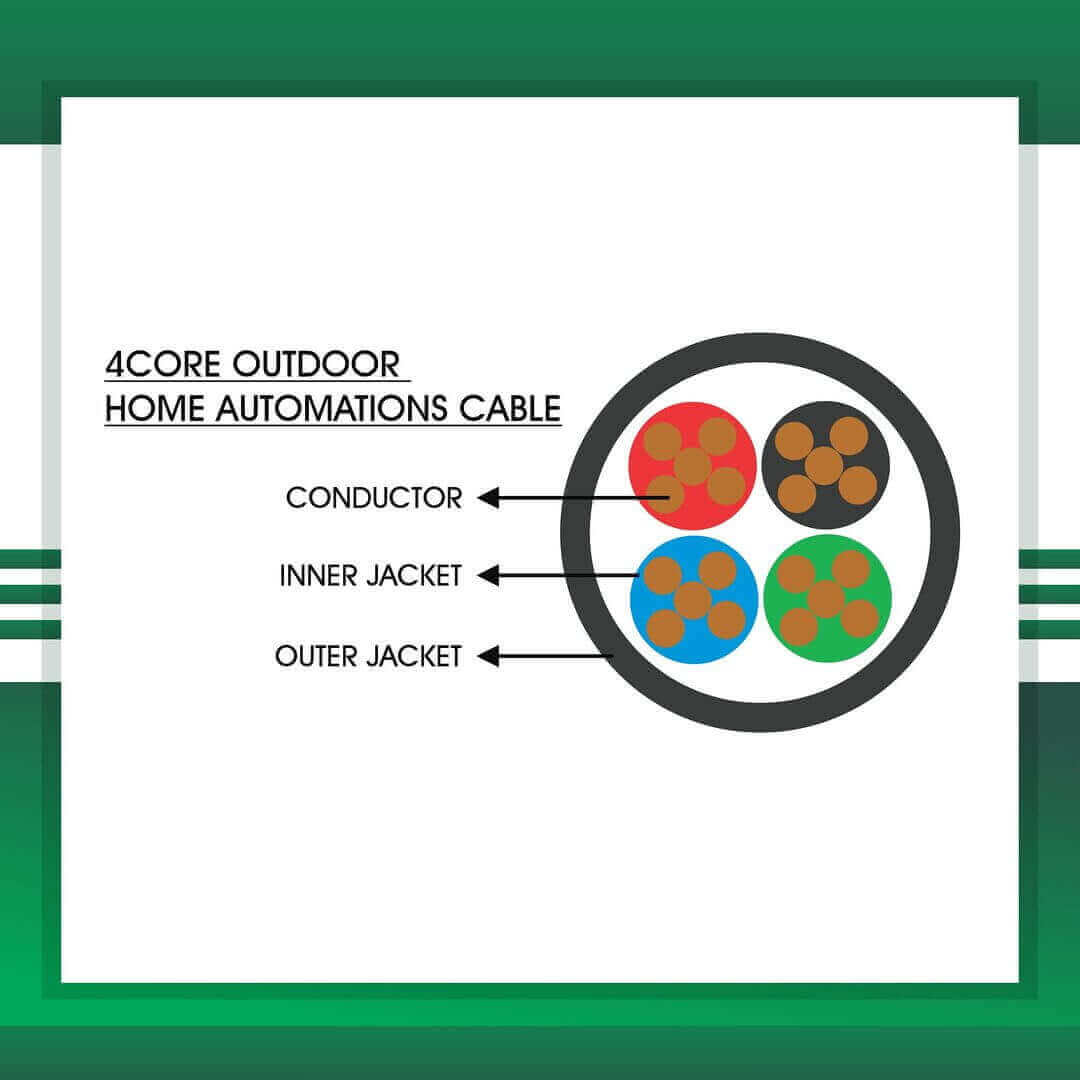

The components of control cables typically include conductors, insulation, shielding, and an outer jacket. The conductors are responsible for carrying the electrical signals, while the insulation prevents short circuits and protects against moisture. Shielding serves to minimize interference, whereas the outer jacket provides mechanical strength and chemical resistance. Each of these components is vital in ensuring that control cables function effectively and withstand the demands of their environment.

An essential aspect of control cables is their application in critical systems. In telecommunications, they are fundamental in connecting networks, ensuring seamless communication. In the automotive industry, control cables facilitate numerous functions, from throttle control to electronic sensor management. Similarly, in industrial equipment, they are instrumental in operating machinery, thus impacting productivity and safety. Consequently, maintaining high-quality standards in the production of control cables is paramount, as substandard cables can lead to system failures and significant operational disruptions.

Manufacturing Process of Control Cables

The manufacturing process of control cables at TMT Global Technology Ltd is carefully structured to ensure that each product meets the highest quality standards. This process begins with the selection of raw materials, where the company emphasizes using premium-grade components, including high-quality copper for conductors and durable insulating materials. The selection process involves stringent quality checks to ensure that all materials meet industry specifications and contribute to the overall performance of the control cables.

Once the raw materials are procured, the next stage involves the extraction and preparation of the copper conductors. The conductors are drawn through dies to achieve the desired gauge, ensuring they are both lightweight and efficient in conducting electrical signals. After this, the conductors are twisted together, which enhances their flexibility and creates the necessary configurations required for specific applications.

Following the preparation of conductors, insulation is applied using advanced extrusion techniques. This stage is crucial, as high-quality insulation provides protection against environmental factors, prevents short circuits, and ensures safety during operation. TMT Global Technology Ltd employs state-of-the-art machinery that allows for precision in the insulation process, thus guaranteeing uniform thickness and optimal performance across the entire length of the cable.

The next phase is the assembly, where multiple insulated conductors are bundled together to form a complete control cable. To enhance reliability, TMT Global Technology Ltd incorporates additional layers for mechanical protection and shielding, depending on the intended application of the cables. This assembly process is overseen by skilled technicians using automated equipment, ensuring a consistent and reliable outcome.

Finally, each batch of control cables undergoes rigorous testing to verify their performance and adherence to regulatory standards. This includes testing for electrical resistance, insulation integrity, and mechanical strength. By employing comprehensive testing methodologies, TMT Global Technology Ltd assures customers of the durability and quality of its control cables, reinforcing its commitment to excellence in manufacturing.

Quality Assurance at TMT

TMT Global Technology Ltd places a strong emphasis on quality assurance throughout its control cable manufacturing process. The organization adheres to a comprehensive framework of industry standards and certifications that validate its commitment to producing high-quality products. By aligning with standards such as ISO 9001, TMT ensures that its production processes meet international quality benchmarks, facilitating the continuous improvement of its offerings. This adherence to established guidelines demonstrates TMT’s dedication to delivering control cables that customers can trust.

The quality assurance process at TMT begins long before the cables reach the final stages of production. Rigorous testing protocols are implemented to monitor various stages of manufacturing. Each control cable undergoes a series of tests to verify its specifications, performance, and durability. For instance, TMT utilizes advanced laboratory equipment to conduct electrical, thermal, and mechanical testing. This ensures that the control cables not only comply with regulatory requirements but also meet the specific needs of critical applications across various industries.

In addition to internal testing, TMT collaborates with external testing facilities to perform comprehensive evaluations of their control cables. These partnerships enable the company to obtain independent verification of their products’ quality and reliability. Certifications from recognized testing organizations further reinforce the integrity of TMT’s control cables, assuring clients that each product delivers optimal performance under demanding conditions.

The meticulous attention to quality assurance at TMT not only enhances the reputation of the company but also instills confidence in customers who depend on these cables for safety and effectiveness in their applications. By ensuring that each control cable meets rigorous specifications through robust testing and industry-standard certifications, TMT Global Technology Ltd continues to set a benchmark in the field of cable manufacturing.

Innovations in Control Cable Technology

TMT Global Technology Ltd has been at the forefront of advancements in control cable technology, continuously evolving its design and manufacturing processes to meet the demands of various industries. The company has implemented several innovative technologies that enhance the performance, durability, and efficiency of control cables. These innovations focus on material selection, manufacturing processes, and the incorporation of smart technology.

One area where TMT has made significant strides is in the utilization of high-quality materials. The use of materials with improved insulation properties has led to better resistance against environmental factors such as extreme temperatures, moisture, and chemicals. This enhances the longevity and reliability of their control cables in harsh conditions. Furthermore, TMT’s commitment to sustainability is evident through the incorporation of recyclable materials in cable production, thereby reducing the environmental footprint of their products.

In addition, TMT has embraced advanced manufacturing techniques, such as precision extrusion and automated quality control systems. These processes ensure tighter tolerances and better performance characteristics. The company continually invests in research and development to refine these methods, thereby increasing the efficiency of production workflows while reducing waste and costs.

The integration of smart technology into control cables represents another significant innovation by TMT. By incorporating sensors within the cables, TMT enables real-time monitoring of cable performance, facilitating predictive maintenance and reducing downtime. This technological advancement not only meets the current market needs but also anticipates future demands in industries that require robust and smart solutions.

Ultimately, TMT Global Technology Ltd’s innovations in control cable technology signify a commitment to enhancing not only the functionality of its products but also to addressing emerging market trends and expectations in various sectors.

Applications of TMT Control Cables

TMT Global Technology Ltd produces a diverse range of control cables that find applications across multiple industries due to their high-quality design and reliability. One significant area of application is in robotic systems, where TMT’s control cables facilitate communication and power transfer between various components. In robotic applications, these cables ensure precise control and coordination, which are crucial for the seamless operation of advanced robotic arms and automated systems.

Additionally, TMT control cables play a vital role in industrial automation. With the rise of automated manufacturing processes, the need for robust control cables has become increasingly critical. These cables are integral in connecting various sensors, actuators, and controllers within the machinery, allowing for real-time data transmission and control. The durability and flexibility of TMT control cables make them ideal for harsh industrial environments, ensuring consistent performance even under extreme conditions.

Another prominent sector that benefits from TMT’s control cables is telecommunications. In this industry, the demand for reliable data transmission is paramount. TMT’s control cables are utilized in network infrastructure, aiding in the connection of various telecommunication devices and systems. Their performance characteristics support high-speed data transfer while maintaining signal integrity, making them suitable for both wired and wireless communication setups.

Moreover, TMT control cables are increasingly employed in the energy sector, particularly in the control systems of renewable energy installations such as wind turbines and solar power plants. By ensuring effective communication between monitoring systems and control mechanisms, these cables contribute significantly to the efficiency and reliability of energy production processes.

In conclusion, the versatility of TMT control cables across diverse industries highlights their essential role in facilitating the functionality and reliability of various systems, from robotics to telecommunications and beyond.

Customer Testimonials and Case Studies

TMT Global Technology Ltd has garnered a reputation for manufacturing high-quality control cables, and the feedback from clients highlights this commitment. Customers across various industries appreciate the effectiveness and reliability of TMT’s control cable solutions. For instance, an engineering firm involved in a complex construction project required durable cables that could withstand extreme environmental conditions. They chose TMT’s control cables for their proven resilience and were impressed with their operational performance. As one project manager noted, “The TMT cables not only met our quality standards but exceeded our expectations in terms of reliability, ensuring smooth operations throughout the project.”

In another notable case, a manufacturing plant faced ongoing issues with cable failures that led to costly downtimes. After switching to TMT’s control cables, the facility reported a significant reduction in maintenance costs. The operations manager shared, “Since integrating TMT’s control cables into our production lines, we have experienced uninterrupted functionality. The reduction in failures has not only improved our efficiency but also bolstered our bottom line.”

Moreover, a utility company that specializes in electrical distribution noted the impact of TMT’s control cables in streamlining their operations. They adopted the cables for their ability to deliver reliable performance in high-load situations. Representatives from the utility reported, “The transition to TMT’s control cables has enabled us to enhance our service delivery. We can now provide our clients with reliable solutions, significantly reducing our response times during outages.”

These testimonials and case studies demonstrate TMT Global Technology Ltd’s dedication to providing control cables that offer both reliability and efficiency across various sectors. The positive experiences of clients underscore the benefits of choosing TMT’s products, confirming that they are an investment in quality and performance.

Environmental Commitment and Sustainability Practices

TMT Global Technology Ltd recognizes the critical need for environmental sustainability in today’s manufacturing landscape, particularly in the production of control cables. The company is dedicated to minimizing its carbon footprint while ensuring that its products meet the highest performance standards. By employing eco-friendly manufacturing processes, TMT Global aims to contribute positively to the environment while maintaining efficiency in production.

One significant aspect of TMT Global’s sustainability practices is their commitment to utilizing materials that are both durable and environmentally friendly. The company sources recycled materials when feasible, which minimizes waste and reduces the demand for virgin resources. By integrating sustainable materials into their control cables, TMT Global supports the circular economy and plays a vital role in conserving natural resources.

Moreover, TMT Global Technology Ltd has implemented several waste reduction techniques throughout its manufacturing operations. This includes optimizing production processes to minimize scrap material and utilizing closed-loop systems for reusing water and other resources. The company’s manufacturing facilities are also equipped with energy-efficient machinery that reduces energy consumption and enhances overall productivity.

In addition to these measures, TMT Global actively participates in various environmental initiatives that promote sustainability within the industry. They continuously explore innovative technologies and practices aimed at further reducing the environmental impact of their operations. This commitment extends beyond the production phase, as TMT Global also emphasizes the importance of responsible product disposal and recycling at the end of the control cables’ life cycle.

By prioritizing sustainability and adopting eco-friendly practices, TMT Global Technology Ltd not only adheres to current environmental regulations but also sets a benchmark for the industry, showcasing its dedication to creating a more sustainable future.

Conclusion and Future Outlook

In examining the control cables manufactured by TMT Global Technology Ltd, a clear picture emerges of a company deeply engaged in innovations that drive the industry forward. TMT has not only maintained a solid reputation for quality and reliability but has also consistently invested in research and development to refine its product offerings. These control cables are critical components across various sectors, including telecommunications and industrial automation, ensuring seamless connectivity and operational efficiency.

As we delve into future trends impacting control cable manufacturing, it is evident that technological advancements will play a pivotal role. The emergence of smart technologies, particularly within the Internet of Things (IoT) framework, demands more sophisticated control cable solutions that can handle increased data transmission while ensuring security and reliability. TMT plans to enhance its existing product lines to accommodate these evolving standards, leveraging its position in the market to provide cutting-edge solutions that align with customer needs.

Moreover, as sustainability becomes a significant focal point in manufacturing, TMT Global Technology Ltd recognizes the importance of eco-friendly practices. The company is actively exploring materials and processes that minimize environmental impact while maintaining product integrity. This proactive approach not only aligns with global sustainability goals but also sets TMT apart as a forward-thinking leader in the control cable market.

In light of these developments, the outlook for TMT Global Technology Ltd appears promising. By adapting to the technological advancements and market demands, the company is poised to maintain its competitive edge. Ultimately, through ongoing innovation and commitment to quality, TMT aims to solidify its position as a trusted provider in the control cable industry, effectively navigating the complexities of tomorrow’s market landscape.